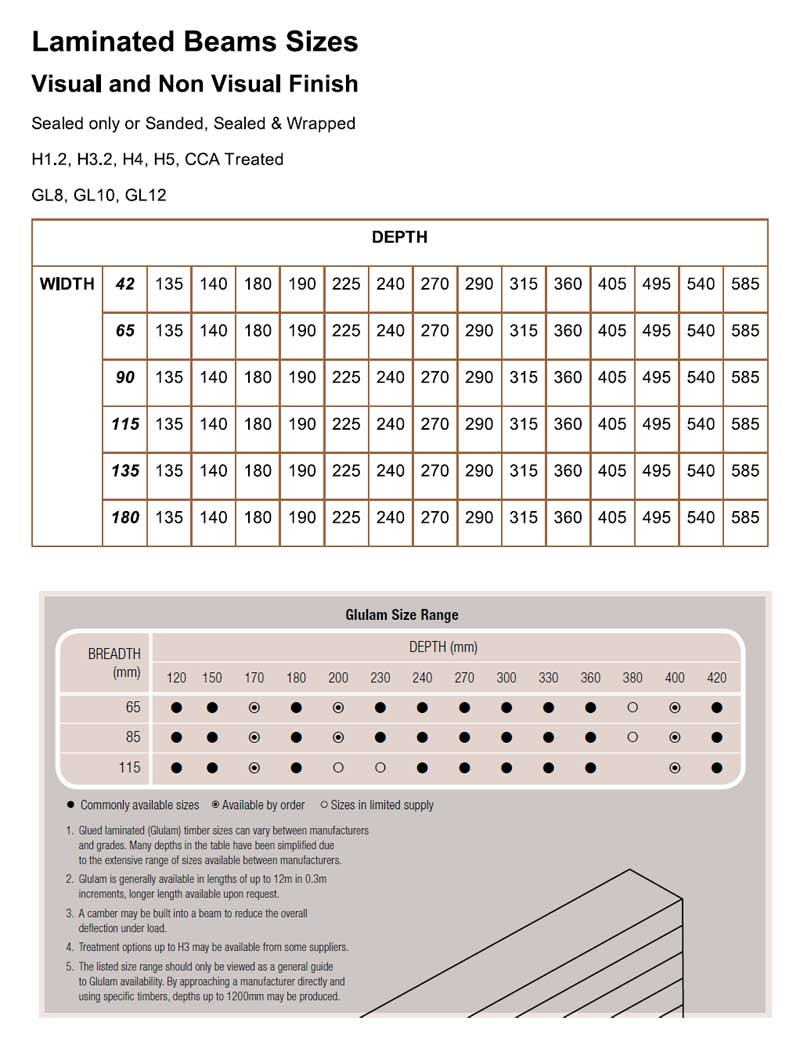

Laminated beams sizes visual and non visual finish sealed only or sanded sealed wrapped h1 2 h3 2 h5 cca treated gl8 gl10 gl12 depth width 42 135 140 180 190 225 240 270 290 315 360 405 495 540 585 65 135 140 180 190 225 240 270 290 315 360 405 495 540 585.

Glulam beam sizes nz.

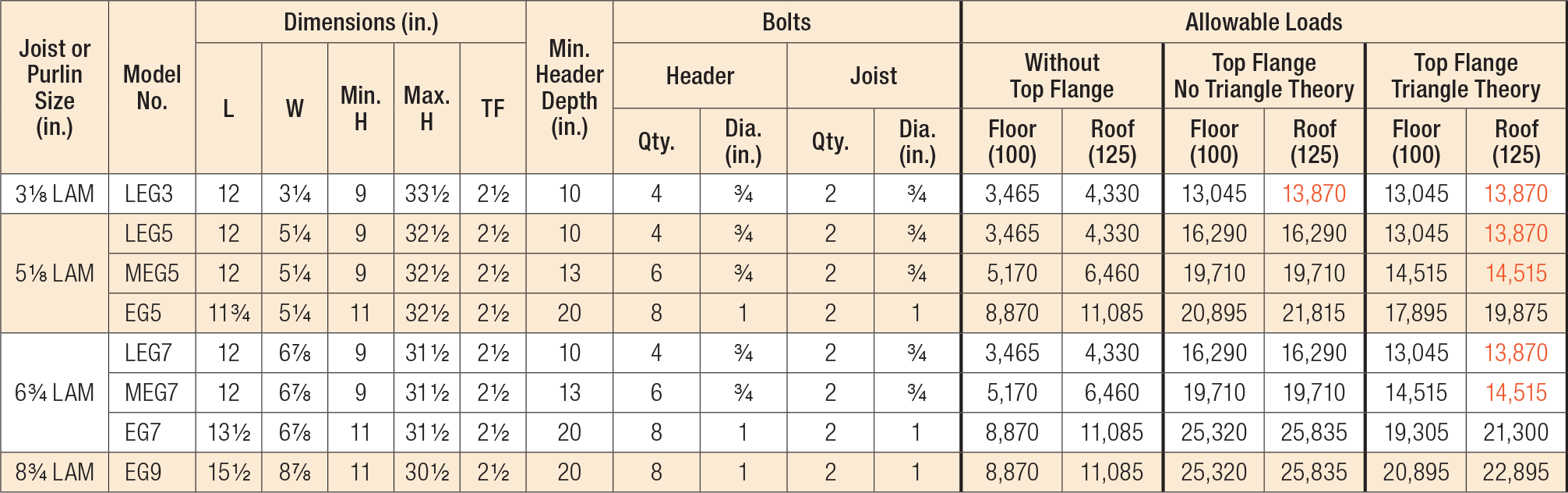

3 1 8 3 1 2 5 1 8 5 1 2 and 6 3 4 inches.

5 boise glulam product guide feb 2010 dimensional tolerances the tolerances permitted at the time of manufacture per ansi standard a190 1 92 are as follows.

Known as the original engineered and glue laminated hardwood beam hyne beam 21c has a superb record for strength and.

240x85 in 4 8 5 4 6 0m lengths 260x85 in 5 4m length 300x85 in 5 4 6 0 7 2m lengths.

Stock beams are manufactured in commonly used dimensions and cut to length when the beam is ordered from a distributor or dealer.

Prolam pl12 glulam beams.

Boise glulam beam products are manufactured with exterior grade or wet use adhesives that comply with all recognized standards.

Glulam is available in both custom and stock sizes.

Prolam pl8 glulam beams.

Typical stock beam widths used in residential construction include.

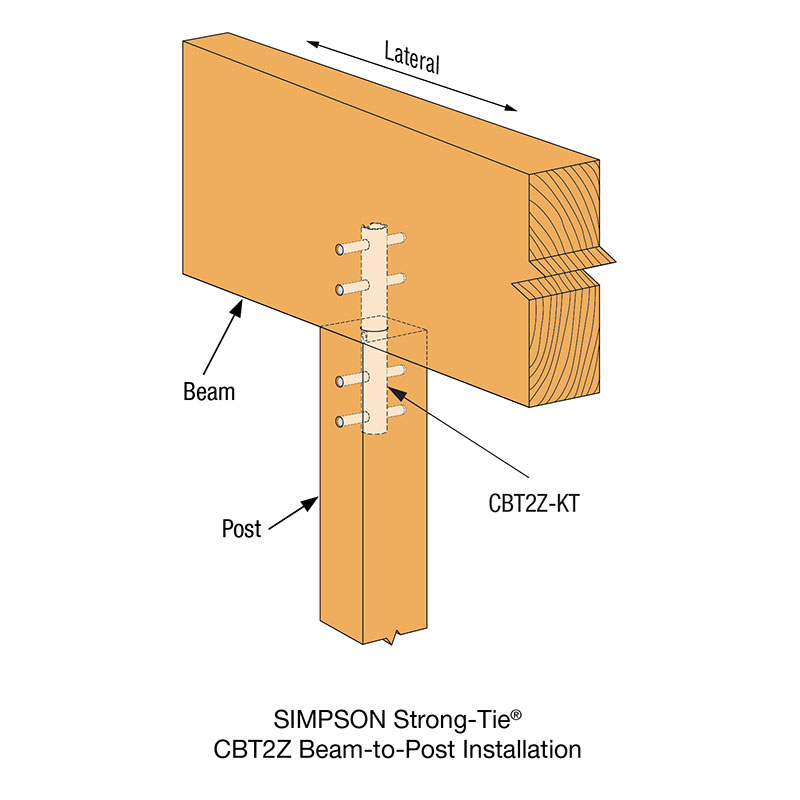

Read more ibuilt glulam post.

Width plus or minus 1 16 of the specified width.

Ibuilt glulam posts are nz made from northern radiata pine.

Our beams are manufactured in a variety of widths and depths with lengths up to 66 feet with or without camber.

Read more lintel 17.

Glue laminated glulam beams timber technologies glue laminated beams are superior in all strength characteristics to solid sawn lumber and pound for pound stronger than steel.

They are laminated visual posts treated to h5 ground contact.

Glulam is treated to h1 2 meeting the strict new zealand building codes.

Depth plus 1 8 per foot of depth minus 3 16 or 1 16 per foot of depth whichever is larger.

The benefit of the boise glulam beams is the flexibility of the product.

Structural timber nz techlam nz s largest glulam timber manufacturers providing high quality structural timber throughout nz and globally.

Length up to 20 feet plus or minus 1 16.

Our titan timber beams resist checking and twisting and are job site ready with one piece construction and more cost efficient than lvl and psl.

That s why it s new zealand s leading structural timber product.

When it comes to structural components few can match the quality of prolam.